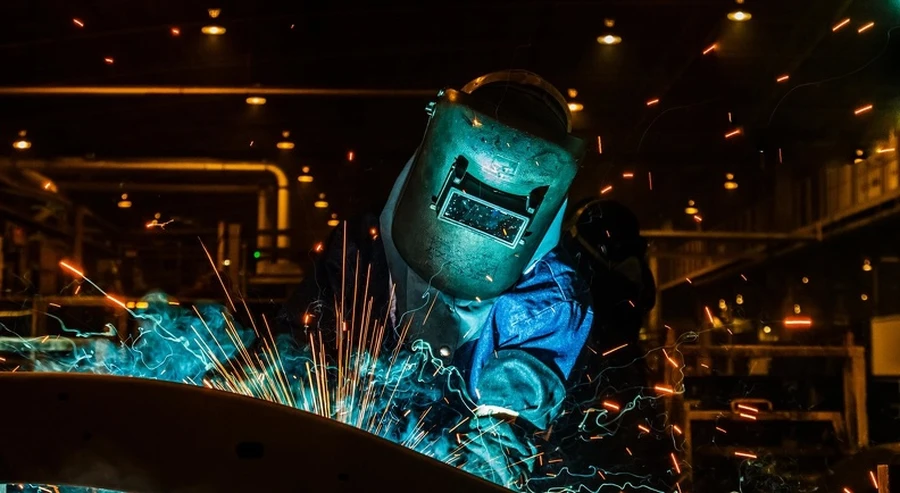

Identifying the Characteristics of a Quality Weld

Welding is a crucial process in many industries. It holds components together, ensuring strength and durability. But how can you tell if a weld is good? Understanding this helps in maintaining safety and performance. A quality weld looks smooth and consistent. It should be free of defects like cracks or porosity. When a weld meets these criteria, it contributes to the overall integrity of the structure.

Visual Indicators of a Quality Weld

A good weld has distinct visual characteristics. The bead should have uniform width, with little to no spatter around it. Moreover, the bead’s profile should be flat or slightly convex, which indicates proper fusion. An inconsistent bead may need welding repair to correct issues before they become problematic.

The Importance of Consistent Bead Appearance

Consistency in bead appearance is vital. It shows that the welder maintained a steady hand and correct technique throughout the process. This consistency means that there are no weak spots in the weld, which could lead to failures under stress. If inconsistencies appear, it might indicate a need for welding repair to ensure safety and reliability.

Understanding Surface Irregularities

Surface irregularities can be a red flag. These include excessive spatter, rough edges, or visible cracks. Such signs suggest that the weld may not hold up over time. In industries where safety is paramount, ignoring these flaws can lead to catastrophic failure.

Essential Attributes of Strong Welds

Strong welds have essential attributes that support their durability. These include adequate penetration, which ensures the weld bonds well with the base materials. They also display uniform heat distribution, preventing any section from becoming brittle or too soft.

- Smooth surface finish with minimal defects

- Uniform thickness across the joint

- No visible cracks or incomplete fusion

Evaluating Penetration Depth

The depth of penetration is crucial in assessing weld quality. Proper penetration means the weld fully fuses with the base metal, providing maximum strength. Shallow penetration might require further inspection and possibly corrective measures to prevent future issues.

Common Issues Affecting Weld Quality

Several common issues can affect weld quality. These include incorrect settings on welding equipment, improper joint preparation, and inadequate cleaning of surfaces before welding. Each issue can introduce defects into the weld, compromising its effectiveness.

- Check equipment settings regularly

- Prepare joints properly before welding

- Clean all surfaces thoroughly

Improving Weld Quality With Best Practices

Adopting best practices can significantly enhance weld quality. Use appropriate protective gear to maintain focus and safety during welding. Always inspect equipment before use to ensure it’s functioning correctly. Regular training for welders can also improve techniques, leading to better outcomes.

Professional Assessment for Quality Assurance

A professional assessment can help assure weld quality. Experts know what to look for and can spot potential problems early on. This proactive approach prevents costly repairs and ensures long-term reliability of welded structures.

Take Action for Superior Welding Outcomes

Ensuring high-quality welds involves understanding key characteristics and addressing issues promptly. Located in Brooklyn, NY, our team at Laseelle's Welding & Iron Works specializes in providing comprehensive solutions for your welding needs. Contact us at (718) 940-0022 for expert advice and services tailored to ensure your projects meet the highest standards of safety and performance.